Are you looking to significantly enhance your biomass pellet production output while reducing energy consumption? In this comprehensive guide, we'll share expert strategies that can help you boost your biomass pellet production efficiency by up to 30%. Learn how to optimize your operations, improve machine performance, and maximize your return on investment.

Optimize Raw Material Preparation

The foundation of efficient biomass pellet production begins with proper raw material preparation:

• Control Material Hardness: Prevent overly hard materials from entering the production process to reduce wear and energy consumption.

• Manage Particle Size: Screen materials beforehand to avoid excessively large particles that can decrease production efficiency.

• Optimize Moisture Content: Maintain optimal moisture levels between 12%-20% for best results. Materials with high moisture content should be sun-dried or pre-dried to prevent them from sticking to the inner walls of the pelleting chamber. Material beyond 30% moisture significantly reduces efficiency and can cause host machine stalling.

Enhance Machine Performance and Operation

Proper machine configuration and operation are crucial for maximizing productivity:

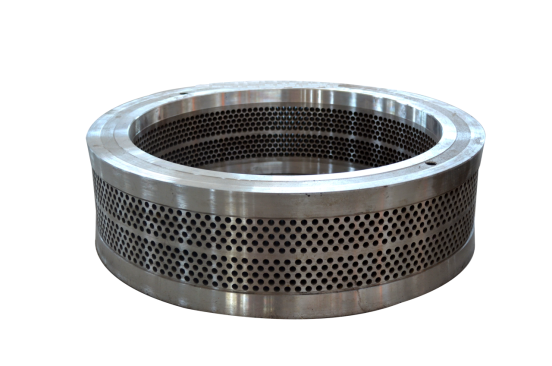

• Select Appropriate Die Holes: Choose the right die hole diameter for your specific application. Using excessively small apertures can result in low output or even complete failure to produce pellets.

• Adjust Roller and Die Clearance: Maintain proper clearance between the roller and die. Too much space causes material slippage and reduced production, while too little clearance leads to rapid temperature increase, material drying, and clogged die holes. The optimal adjustment is to have the rollers rotating without slipping but not forced.

• Implement Uniform Feeding: Ensure consistent and uniform feeding of material to maintain smooth operation and keep the machine running at optimal speed.

• Monitor Electrical Current: Keep the host motor current within rated voltage limits during production. Adjust feeding speed according to current readings to prevent machine jams.

Leverage Advanced Technologies

Consider technological improvements that can dramatically increase efficiency:

• Mobile Pelleting Technology: Recent research shows that mobile pelleting technology can reduce energy input by 44% and improve Energy Efficiency Ratio (EER) by 84% compared to traditional stationary production lines.

• Improved Roller Pressure Design: Enhancements in roller pressure design that increase pressure while reducing ineffective wear can create more effective compression zones within the pelleting chamber, resulting in higher material output rates.

• Efficient Transmission Systems: Improve transmission system efficiency to increase the actual useful power of the pellet machine, achieving energy savings and consumption reduction.

Implement Regular Maintenance and Lubrication

Consistent maintenance is essential for sustained high performance:

• Regular Lubrication: Apply high-temperature resistant grease to the host machine's two rollers every 4-5 hours. For other components, follow a strict lubrication schedule: feed motor (weekly), silo and airlock chain wheel (every 3 days), conveyor belt (daily).

• Continuous Operation: For sustained production, it's recommended to run the machine for about ten hours before stopping for maintenance.

• Clean Dies Regularly: Regularly clean templates to maintain optimal production efficiency.

Energy Efficiency Considerations

Implement these strategies to reduce energy consumption:

• Heat Recovery Systems: Collect and reuse waste heat from dryers and pellet machines to preheat incoming materials or for other heating needs.

• Improved Heat Exchange Systems: Use efficient heat exchangers and clean them regularly to maintain good heat transfer performance.

• Optimized Drying Process: Precisely control drying temperature and time based on the initial moisture characteristics of raw materials.

• Equipment Sealing: Modify equipment seals to reduce air leakage and improve energy utilization.

Advanced Process Optimization

For those looking to further enhance their production:

• Legume-Grass Combinations: Research has shown that combining legume and grass species (like fodder galega and bromegrass) can provide optimal yield stability and resistance to adverse conditions while achieving an energy efficiency ratio of up to 13.07 with mobile pelleting technology.

• Binder Optimization: Studies indicate that binder quantity significantly affects machine efficiency, throughput, and pellet length. While increasing binder improves pellet length, it may decrease machine efficiency and throughput.

• Innovative Pelletizing Methods: Some new methods allow pelleting at 10-35% humidity in a single step, eliminating the need for drying. These methods only increase temperature by 10-15°C, producing pellets at just 55-60°C that can be packaged directly without cooling.

By implementing these expert strategies, you can significantly improve your biomass pellet production efficiency, reduce energy costs, and enhance your overall operational profitability. Remember that optimal results come from a holistic approach that combines proper material preparation, machine optimization, regular maintenance, and the adoption of innovative technologies.

About Shandong Rotexmaster Machinery Co., Ltd.

Shandong Rotexmaster Machinery Co., Ltd., located in Jinan, Shandong, China, is a leading manufacturer of biomass pellet production equipment. Since its establishment in 2008, the company has specialized in producing high-quality wood pellet mills, wood chippers, wood crushers, and hammer mills. With an estimated workforce of 200-300 employees and a factory size of 50,000-100,000 square meters, Rotexmaster has built a strong reputation in the industry. The company exports to multiple countries including Austria, France, Greece, India, and Thailand, demonstrating its global reach and commitment to quality international standards