The Pellet Handbook

Biomass pellet production and comprehensive utilization

1. Global Market Distribution of Biomass Pellets

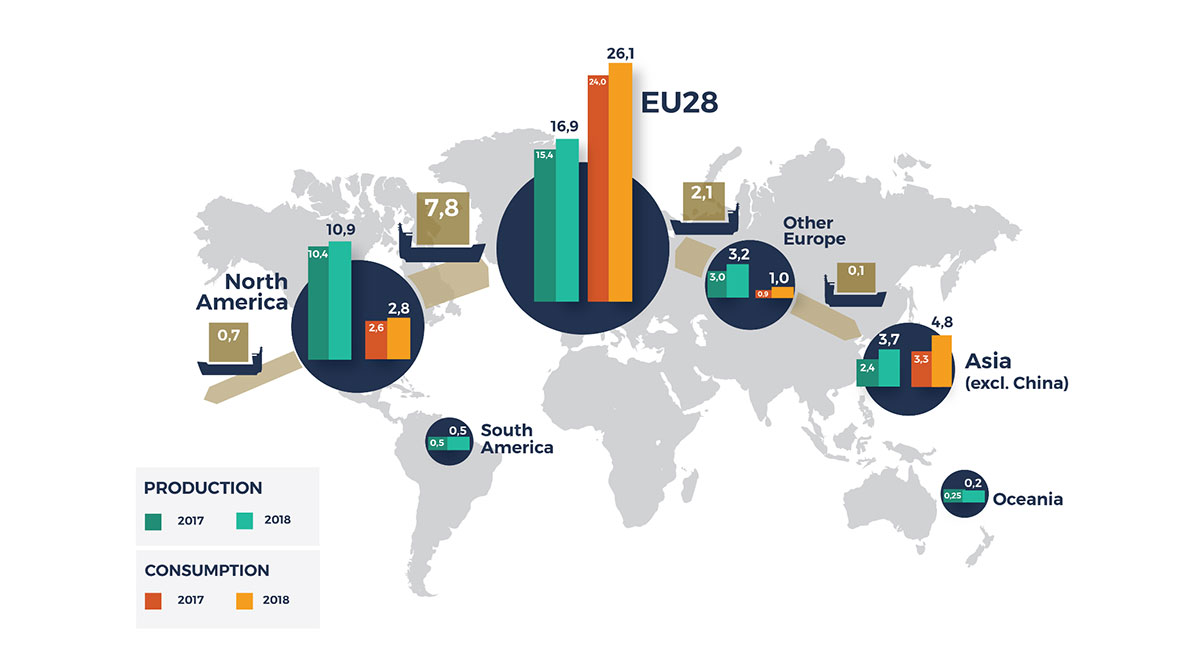

Global wood pellet consumption reached 35 million tonnes in 2020 or +14% compared to its level of 2019.

This total excludes China, although if we were to include China it would have an overall total of 52.746.706 tonnes.

Europe is the largest pellet consumer in the world with 27 million tonnes of pellets being consumed annually.

In 2019, the EU28 saw a significant growth of around 2 million tonnes with the industrial use of pellets being led by the UK. With a production volume of 20,1 million tonnes (16,9 million for the EU28), Europe solely supplies 74% of its pellet use (65% for EU28).

1. The Raw Materials for Biomass Pellet

Raw Material

All kinds of wood

Corn and other straw

Rice Husk

Peanut shell

Shavings

Palm shell

efb

Bamboo

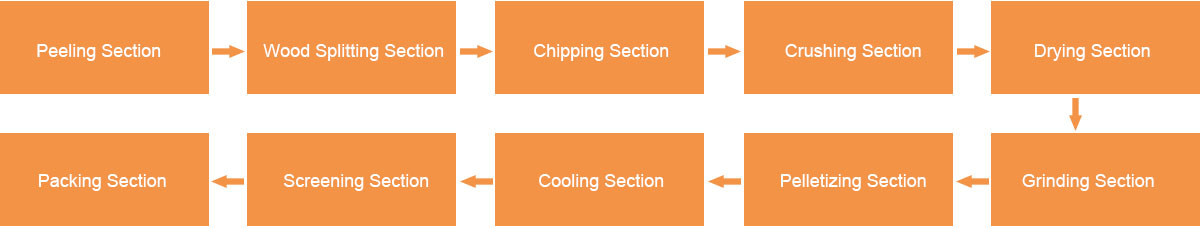

2. Technological Process

3. Project Feasibility Report (Main Cost)

Labor Cost A

| L: | Labor Cost | USD/T |

| S: | Salary of Staff | USD/day |

| n: | Number of Staff | |

| nS: | Total Salary of Staff per Day | USD/day |

| C: | Capacity per Hour | T/Hour |

| H: | Working Hours per Day | Hour |

Electric Fee E

| E: | Electric Fee Cost | USD/T |

| 0.75: | Conversion coefficient (Ratio Between Actual Value and Theoretical Values) | |

| F: | Electric Fee | USD/kw h |

| P: | Total Power | kw h |

| C: | Capacity per Hour | T/Hour |

If you need a project feasibility report, please contact us by email. (Including equipment, consumables, grease loss)

4. Main introduction of the Pellet machine

The Feature of Wood Pellet Machine

Vertical ring die pellet machine consist of a die and roller assmeble ,The die is fixed and the rollers runs around the die.

Loose material is fed into the pelletizing cavity.

Roller rotation pressure force the material through die, compressing it into pellets.

Adjustable knives cut the pellets to the desired length.

No additives are normally used. The lignin in the wood acts as a binding agent as it softens during the pelletizing process .

During press,a certain amount of additional moisture is extracted with the pellet mill.

So, the main tools for pelletising are die and rollers.

Main Technical Parameter of Wood Pellet Machine

Model | YGKJ-880 Wood Pellet Machine |

| Main Power | 220kw |

| Kick off Driver | 3kw |

| Oil Pump | 0.55kw |

| Reducer Oil Pump | 1.5kw |

| Air Fan | 2.2kw |

| Die | Stainless steel (4Cr13) |

| Die Type | Double layer die, longer life time Each layer 7 rows (8mm diameter) |

| Die heat treatment hardness | HRC60-65 |

| Roller Assemble | Alloy Steel |

| Lubrication System | Automatic lubrication pump |

| Dust collecting system | Cyclone, bag dust collector, fan blower system |

| Gear Box | Module increased , gear strengths increasedGear oil recycle used to lubricate main shaft, gears, connections. |

| Rotating speed | 73rmp |

| Pelleting room temperature | 80-100 ℃ |

| Dimension | 3000*1500*2300mm(L*W*H) |

| Weight | 13 ton |

5. Biomass Pellets Standard

| Properties\ rank | unit | A1 | A2 | B |

| Diameter(D) Length(L) | mm | D06, 6 ± 1 | D06, 6 ± 1 | D06, 6 ± 1 |

| 3.15 < L ≤ 40D08, 8 ± 1 | 3.15 < L ≤ 40D08, 8 ± 1 | 3.15 < L ≤ 40D08, 8 ± 1 | ||

| 3.15 < L ≤ 40 | 3.15 < L ≤ 40 | 3.15 < L ≤ 40 | ||

| moisture content | w-% upon receipt, wet | ≤ 10 | ≤ 10 | ≤ 10 |

| ash | w-%, dry | ≤ 0.7 | ≤ 1.2 | ≤ 2.0 |

| Durability | w-% upon receipt | ≥ 97.5 | ≥ 97.5 | ≥ 97.5 |

| fine particles | w-% upon receipt | ≤ 1.0 | ≤ 1.0 | ≤ 1.0 |

| additive | w-% upon receipt (specify the type and amount added) | ≤ 2 | ≤ 2 | ≤ 2 |

| Net calorific value | MJ/kg upon receipt | ≥ 16.5 | ≥ 16.5 | ≥ 16.5 |

| Apparent density | Upon receipt kg/㎥ | ≥ 600 | ≥ 600 | ≥ 600 |

| Nitrogen (N) | w-% dry | ≤ 0.3 | ≤ 0.5 | ≤ 0.7 |

| Sulfur (S) | w-% dry | ≤ 0.04 | ≤ 0.05 | ≤ 0.05 |

| Chlorine (Cl) | w-% dry | ≤ 0.02 | ≤ 0.02 | ≤ 0.03 |

| Arsenic (As) | mg/kg dry | ≤ 1 | ≤ 1 | ≤ 1 |

| Cadmium(Cd) | mg/kg dry | ≤ 0.5 | ≤ 0.5 | ≤ 0.5 |

| Chromium (Cr) | mg/kg dry | ≤ 10 | ≤ 10 | ≤ 10 |

| Copper (Cu) | mg/kg dry | ≤ 10 | ≤ 10 | ≤ 10 |

| Lead (Pb) | mg/kg dry | ≤ 10 | ≤ 10 | ≤ 10 |

| Mercury (Hg) | mg/kg dry | ≤ 0.1 | ≤ 0.1 | ≤ 0.1 |

| Nickel (Ni) | mg/kg dry | ≤ 10 | ≤ 10 | ≤ 10 |

| Zinc (Zn) | mg/kg dry | ≤ 100 | ≤ 100 | ≤ 100 |

| Ash melting point(recommended) | °C | Express | Express | Express |

Europe Pellet Standard

| Property | Unit | ENplus A1 | ENplus A2 | ENplus B | Testing standard 11) |

| Diameter | mm | 6 ± 1 or 8 ± 1 | ISO 17829 | ||

| Length | mm | 3,15 < L ≤ 40 4) | ISO 17829 | ||

| Moisture | w-% 2) | ≤ 10 | ISO 18134 | ||

| Ash | w-% 3) | ≤ 0,7 | ≤ 1,2 | ≤ 2,0 | ISO 18122 |

| Mechanical Durability | w-% 2) | ≥ 98,0 5) | ≥ 97,5 5) | ISO 17831-1 | |

| Fines (< 3,15 mm) | w-% 2) | ≤ 1,0 6) (≤ 0,5 7)) | ISO 18846 | ||

| Temperature of pellets | °C | ≤ 40 8) | |||

| Net Calorific Value | kWh/kg 2) | ≥ 4,6 9) | ISO 18125 | ||

| Bulk Density | kg/m3 2) | 600 ≤ BD ≤ 750 | ISO 17828 | ||

| Additives | w-% 2) | ≤ 2 10) | - | ||

| Nitrogen | w-% 3) | ≤ 0,3 | ≤ 0,5 | ≤ 1,0 | ISO 16948 |

| Sulfur | w-% 3) | ≤ 0,04 | ≤ 0,05 | ISO 16994 | |

| Chlorine | w-% 3) | ≤ 0,02 | ≤0,03 | ISO 16994 | |

| Ash Deformation Temperature1) | oC | ≥ 1200 | ≥ 1100 | CEN/TC 15370-1 | |

| Arsenic | mg/kg 3) | ≤1 | ISO 16968 | ||

| Cadmium | mg/kg 3) | ≤ 0,5 | ISO 16968 | ||

| Chromium | mg/kg 3) | ≤10 | ISO 16968 | ||

| Copper | mg/kg 3) | ≤10 | ISO 16968 | ||

| Lead | mg/kg 3) | ≤10 | ISO 16968 | ||

| Mercury | mg/kg 3) | ≤ 0,1 | ISO 16968 | ||

| Nickel | mg/kg 3) | ≤10 | ISO 16968 | ||

| Zinc | mg/kg 3) | ≤100 | ISO 16968 | ||