The global push towards carbon peak and carbon neutrality ("dual-carbon" goals) demands urgent transformation within the energy sector. Reducing reliance on fossil fuels requires scalable, sustainable alternatives. Biomass energy, derived from organic materials like wood chips, agricultural residues, and dedicated energy crops, stands out as a vital renewable solution. At the heart of unlocking biomass's potential lies a critical technology: the biomass pellet machine.

The Green Energy Imperative and Biomass Potential

Traditional energy sources like coal and oil are major contributors to greenhouse gas emissions. Achieving dual-carbon targets necessitates a significant shift towards renewables. Biomass offers unique advantages:

1.Carbon Neutrality: Plants absorb CO2 during growth, balancing emissions released when biomass is used for energy.

2.Abundant Feedstock: Utilizes waste streams (sawdust, straw, husks) and sustainably grown energy crops.

3.Energy Density: Converting raw biomass into pellets significantly increases its energy density, making storage and transport efficient.

4.Dispatchable: Unlike some renewables, biomass energy can be generated on demand.

The Biomass Pellet Machine: Transforming Waste into Wealth

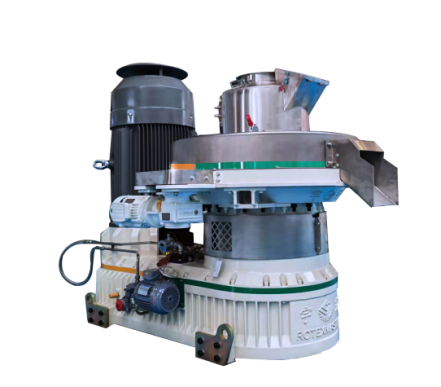

Raw biomass is often bulky, inconsistent in moisture and size, and difficult to handle efficiently. This is where the biomass pellet machine becomes indispensable. These machines compress finely ground biomass material under high pressure and temperature through a die, producing dense, cylindrical pellets.

How Biomass Pellet Machines Drive Green Transformation:

1.Enabling Efficient Combustion: Biomass pellets produced by a biomass pellet machine have uniform size, shape, and moisture content. This consistency allows for:

1)Automated Feeding: Smooth operation in boilers and furnaces designed for pellets.

2)High Combustion Efficiency: Complete burning minimizes waste and maximizes heat output.

3)Reduced Emissions: Cleaner combustion compared to raw biomass, lowering particulate matter and harmful gases.

2.Facilitating Large-Scale Substitution: Pellets are a direct, "drop-in" replacement for coal in many industrial boilers and power plants. The biomass pellet machine makes this substitution viable by producing a fuel that handles similarly to coal but with a drastically lower carbon footprint.

3.Unlocking Waste-to-Energy: Agricultural and forestry residues often pose disposal challenges. The biomass pellet machine transforms this "waste" into a valuable energy commodity, reducing open burning (a major pollutant) and creating rural economic opportunities.

4.Promoting Sustainable Forestry/Agriculture: Demand for pellet feedstock encourages sustainable land management practices and the cultivation of fast-growing energy crops on marginal land, enhancing carbon sequestration.

Environmental & Economic Benefits Amplified

The role of the biomass pellet machine extends beyond fuel conversion:

1.Carbon Reduction: Directly displaces fossil fuels, accelerating progress towards carbon neutrality goals.

2.Waste Minimization: Diverts significant volumes of organic waste from landfills or uncontrolled burning.

3.Energy Security: Diversifies the energy mix, reducing dependence on imported fossil fuels.

4.Rural Revitalization: Creates jobs in feedstock collection, transportation, biomass pellet machine operation, and pellet distribution.

The Future Fueled by Biomass Pellets

As nations intensify efforts to meet dual-carbon targets, the demand for reliable, sustainable biomass energy will surge. Advanced biomass pellet machines are crucial for scaling up production to meet this demand efficiently and cost-effectively. Continuous innovation focuses on:

1.Higher Efficiency: Reducing energy consumption during the pelleting process itself.

2.Broader Feedstock Flexibility: Handling diverse materials (like grasses or certain municipal wastes) effectively.

3.Increased Automation & Durability: Lowering operational costs and improving machine longevity.

Conclusion

The transition to a low-carbon future requires practical, scalable solutions. Biomass energy, powered by the essential technology of the biomass pellet machine, offers a proven pathway. By converting abundant organic residues and dedicated crops into a standardized, high-energy fuel, biomass pellet machines are directly enabling industries and communities to reduce fossil fuel dependence, cut emissions, manage waste effectively, and contribute meaningfully to achieving global carbon neutrality goals. Investing in and deploying this technology is key to greening the traditional energy landscape.

About Shandong Rotexmaster Machinery Co., Ltd.

Shandong Rotexmaster Machinery Co., Ltd. is a dedicated manufacturer of high-quality biomass pellet machines and complete pellet production lines. Committed to supporting the green energy transition, Rotexmaster focuses on robust engineering, reliable performance, and solutions tailored for diverse biomass feedstocks and production scales. Explore their innovative technology designed to help businesses and communities harness the power of biomass energy efficiently. Learn more about their offerings at their website.